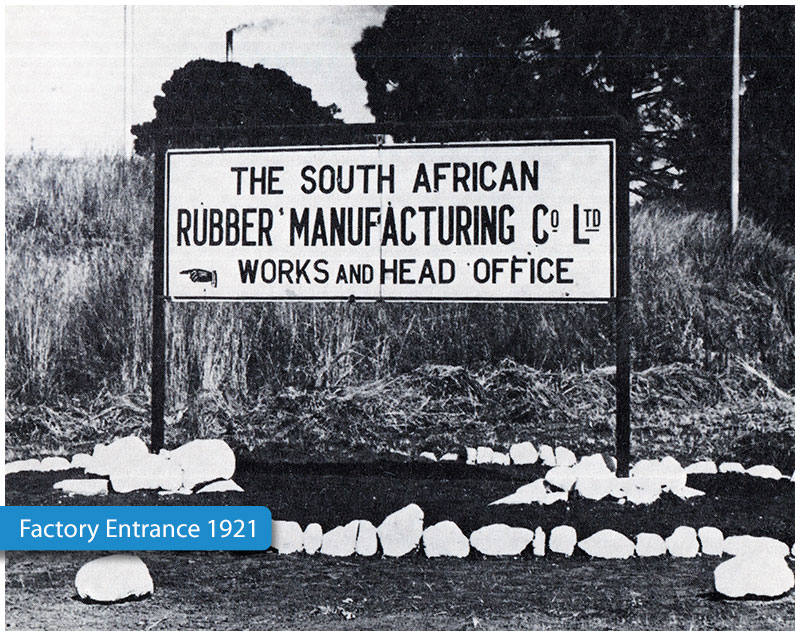

As one of the oldest companies in South Africa, we pioneered the rubber industry in Southern Africa back in 1917 when Godfrey Ferguson and William Rowe Earls, fierce competitors at the time, joined forces and founded the South African Rubber Manufacturing and Tyre Company Limited. It was later to be named the South African Rubber Manufacturing Company Limited on the 5th of December 1918 or SARMCOL, as most people know us today.

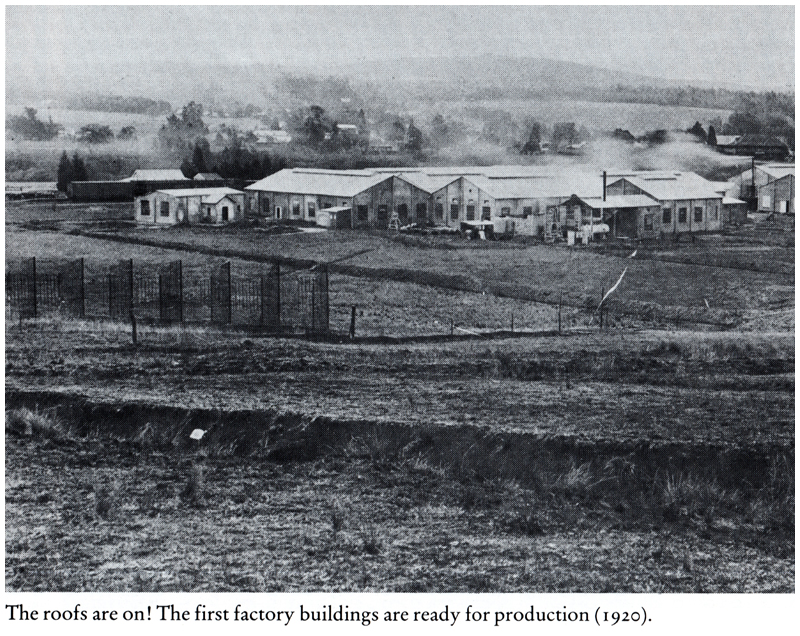

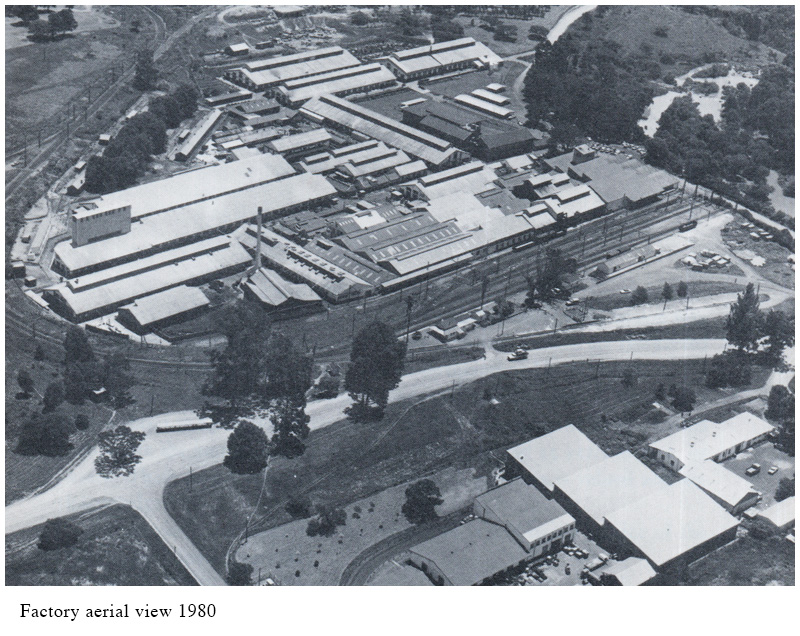

Our factory, officially opened on the 21st of February 1921 on the banks of the Umgeni River in the picturesque town of Howick in KwaZulu Natal. To date SARMCOL is still one of the largest manufacturers of general rubber and specialised products on the continent of Africa.

Set on more than 18 hectares of land which was initially purchased at 10 pounds an acre in 1850, and later discovered as a suitable site for the factory by Dr E.R. Sims, a well-known botanist and advisor on forestry to the government, the factory was strategically set up in its current location to take advantage of the readily available water supply and its potential to generate power to drive all the machinery because of the waterfalls which drops 100 meters down below, making it the ideal location for a hydroelectrical turbine.

On the Eve of the Startx

Despite considerable publicity given to the company’s future programmes, all goods marketed by Sarmcol were produced in Johannesburg in the 1920 period. An official shareholders report dated 14 November 1020 read: “The construction of your new works at Howick has been in progress since the 27th of November 1919 but the work is now rapidly approaching completion.” According to the South African Motorist magazine the official opening took place on 24 February 1921 and a report stated the total value of the machinery was 80 000 pounds at the time.

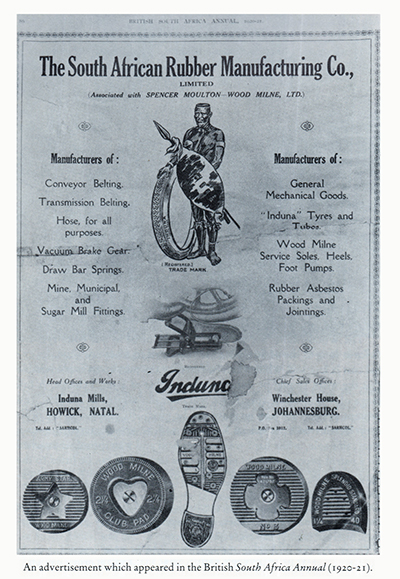

Induna Tyres and Other Goodsx

The Christmas Annual, one of the most popular publicity media existing in South Africa of those days ran an article under “A new industry. Rubber manufacture in South Africa” in 1919. “The plant installed is both complete and up-to-date, and compares favourably with any rubber mill overseas. No expense has been spared in construction and every portion has been laid out with a view to securing the most economical methods of manufacture”. It read. “The Company’s trademark ‘Induna’, is expressive of its policy – ‘always ahead’.

It is intended to place on the market goods of the highest quality and to finish by making every worker a specialist in his particular sphere, thus enabling the production of articles which will be termed ‘flawless’ by their clients.”

Although 1924 saw the last “Induna” tyres to be turned out, the pioneering work was not in vain. Indeed the demonstration given by Sarmcol satisfied the greater overseas manufacturers that such things could be made in South Africa, with the result that 11 years later, in 1935, Dunlop opened up their plant in Durban, followed by Firestone in Port Elizabeth in 1936, Goodyear in 1947 and General Tyre in 1949.

The Delmore Schemex

The biggest news of all was the introduction of the new South African Customs Tariff, which went into effects from 30 July 1925. Under this, practically all raw materials required by Sarmcol, particularly rubber, entered the country duty-free, while imported rubber footwear henceforth paid 10 per cent duty.

All this formed a preliminary to a major property transaction, Sarmcol acquired the extensive works of the New Transvaal Chemical Company Limited at Delmore, two miles from Germiston. The demands of the mines and railways had kept Sarmcol working at full pressure practically all the time. It was now found that it was necessary to have works in the Transvaal for the production of hose for the use in the mines, and for other articles.

The property of the New Transvaal Chemical Works was 53 acres and fully equipped with a model village for employees. Nearly 200 000 pounds had been spent on the property by the late owner who had been in business for 35 years.

Through World War IIx

Overshadowing the scenes of prosperity which returned to South Africa in the later 1930s was a grim spectre overseas – the rise of power on the continent of Europe , of Adolf Hitler and his henchmen.

About two years before the outbreak of the war, in 1937-1938, the government appointed a small body of military and civilian personnel for the purposes of investigating, aided by practical experiments, where desirable, the resources of the Union suitable and available for the production of warlike stores and materials in case of emergency. Apart from the producers of munitions and weapons, many vitally important, but less spectacular enterprises were also involved, one of which was Sarmcol.

By far the most serious problem to confront Sarmcol however, during the entire war period arose after Japan entered into the war. Her ensuing series of victories with appalling speed, robbed the Allied powers, South Africa included, of access to practically the whole Far East, and so also to the world’s major sources of rubber.

Yet in spite of wartime conditions, Sarmcol continued to improve the routine of the factory and its sales organisation. On 1 September 1941, South Africa’s new Factories Act came into force, which considerably raised the benefits for employees.

Industrial Boomx

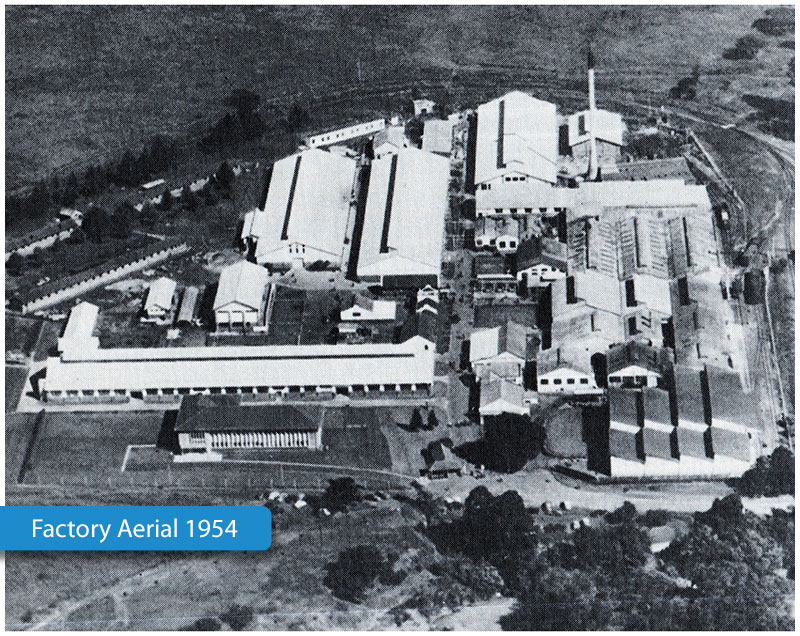

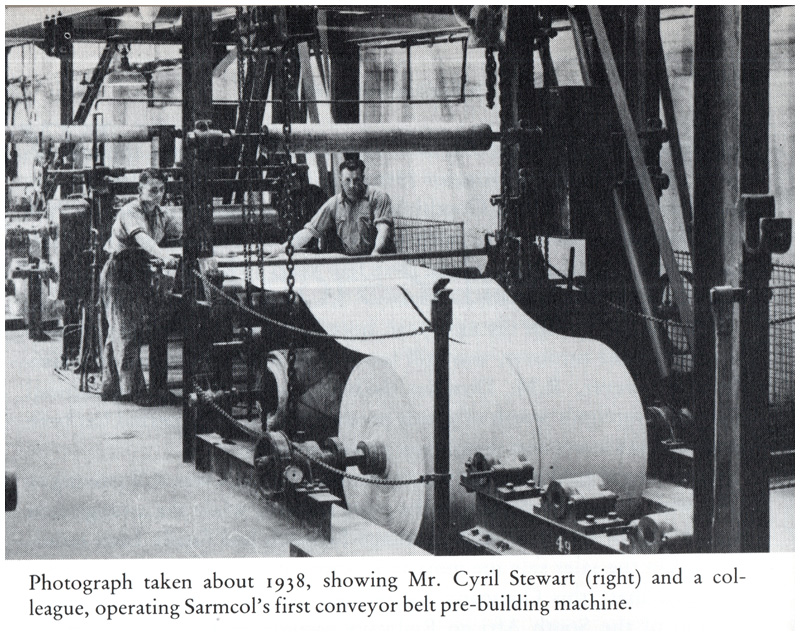

South Africa now entered that unparalleled industrial boom which rendered so memorable the years succeeding the war and which brought a corresponding rise, not only in output figures, but in the size of the staff at Sarmcol.

Amongst the most important innovations at Howick was the Continuous Vulcaniser, put into operation in 1949, for which Sarmcol held the sole operating rights in South Africa.

Proof of the international scope Sarmcol had achieved was a giant conveyor belt put into use on the copper mines of the Belgian Congo. Weighing 8 tons and being 1,674 feet long, it was too big to be carried on and ordinary railway truck.

By 1951 the floor space at Howick had grown to 225,000 square feet and the staff complement exceeded 1500 people.

Post – War Milestonesx

- According to a 1952 catalogues Sarmcol’s product range exceeded 5000 different items.

- August of 1960 Sarmcol received an invitation by the Industrial Development Corporation of South Africa to participate in the establishment of the state-backed Synthetic Rubber Development Company.

- 1964 Sarmcol decided to produce a publicity film, the first ever to be made in South Africa

- The celebration of the 50th jubilee in 1969

- 1971 saw the installation of the first computer

- Following the introduction in 1977 by the SABS of a new specification, “setting out minimum standards of quality for general purpose textile reinforced conveyor belting”, another new one came into use, known as Powaply.

- Sarmcol was also responsible for developing Monolok conveyor belting and Powadrive vee and wedge belts

- A range of products designed for the lining of dams, canals, roofs and related waterproofing purposes developed into a major product range too. The most important of these Butyl sheeting.

Since its establishment in 1921, the factory has grown exponentially over the past 100 years, and has played its part in the history of South African industrialisation and has become a recognised institution with a colourful history and legacy. From the beginning it was driven by entrepreneurs, innovators and hard-working men and women for many generations of South Africans.

Today still housing a total of 60 000 m2 under-roof and providing world-class products for Africa and the world, Sarmcol is once again taking to the global stage, to build and grow a new legacy with a wide range of rubber beltings to hoses, sheeting and numerous components for the mining, agricultural, automotive and general industries.